Tuesday, January 08, 2008

Wednesday, May 31, 2006

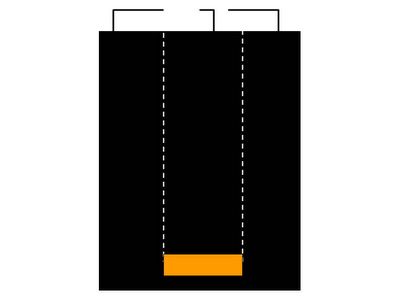

Good Stove Portable

A portable "Good Stove" has been designed. This is for the convinence of some families who prefer to cook outdoors and would like to shift thier stove inside their house during the rainy days. The design is same as that of "Good Stove" except that it is a simple single stove.

Material required

A 15 liters tin can (most commonly available in India) costing about Rs. 10 to 20.

2 kgs cement, 4 kgs sand (Good Clay is another option)

6 bricks and gravel

3 nos 6 inchs length and 1/2 inch diameter steel - for making a stand for keeping the pot

Two 3 feet lenght and 3.5 to 4 inches diameter PVC pipes for moulding the elbow, which will be removed can be reused several times.

Time to make the Stove :

Half an hour

The Stove will be ready to use in next two to three days after curing with water.

Total cost about: $1

Advantages : All the above raw material is easily available in every village, even if the tin can gets rusted, the mould remains and can be maintained easily.

There is demand from the small families (4 to 5 members) and also those having alternative energy options would like to have one as standby.

Material required

A 15 liters tin can (most commonly available in India) costing about Rs. 10 to 20.

2 kgs cement, 4 kgs sand (Good Clay is another option)

6 bricks and gravel

3 nos 6 inchs length and 1/2 inch diameter steel - for making a stand for keeping the pot

Two 3 feet lenght and 3.5 to 4 inches diameter PVC pipes for moulding the elbow, which will be removed can be reused several times.

Time to make the Stove :

Half an hour

The Stove will be ready to use in next two to three days after curing with water.

Total cost about: $1

Advantages : All the above raw material is easily available in every village, even if the tin can gets rusted, the mould remains and can be maintained easily.

There is demand from the small families (4 to 5 members) and also those having alternative energy options would like to have one as standby.

Subscribe to:

Comments (Atom)